HYDRO POWER

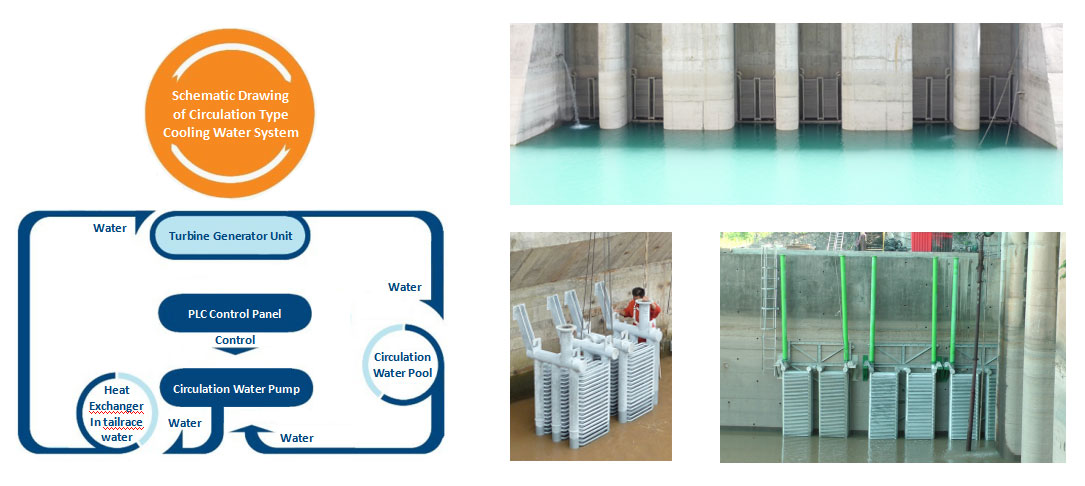

Cooling Water System

Most of the hydro power stations are generating maximum power during the rainy season when water is heavily laden with silt and floaters. It has been observed that if the open loop cooling water system is used under these circumstances, very often blockage of filters, heat exchangers and erosion of exchanger tubes / cooling water pumps leads to frequent breakdown. This finally leads to colossal generation losses.

In order to overcome these problems closed loop cooling water system has been highly recommended. However, when pumping is used on primary water side, associated problems of silt and floaters not only affects the performance of cooling water system to some extent but also leads to excess auxiliary power consumption due to additional pumping requirements on the primary water side.

Further, additional space is also required to accommodate Heat exchangers (between primary and secondary water) and associated pumping and piping.

The comparison between the submersible circulation cooling water system and the traditional cooling water supply system is as follows:

|

The Submersible Circulation Cooling Water Supply System |

The Traditional Cooling Water Supply System |

|

| 1 |

The quality of water is quite good, and it fully satisfies the requirement of cooling water system for the unit. |

The water may be silt laden not meeting the requirement the cooling water system. |

| 2 |

Blockage of cooler tubes will never happen in the system. |

Blockage of coolers etc. may happen because of the floater, sediments etc. |

| 3 |

Floaters can be prevented to go into the coolers. |

Floater can not be prevented. |

| 4 |

Free from sand and sediment. |

Sand and sediment can not be avoided. |

| 5 |

Scale formation can be prevented. |

Scale formation can not be prevented. |

| 6 |

Aquatic organism can be prevented. |

Aquatic organism cannot be prevented. |

| 7 |

Moisture condensation can be prevented. |

Moisture condensation can not be prevented. |

| 8 |

It will not get effected in flood season and low water season. |

It will be greatly affected in flood season and low water season. |

| 9 |

Easy operation, maintenance, and repair. |

Difficult operation, maintenance, and repair due to problems related to silt/floaters. |

| 10 |

Energy saving |

No energy saving |

| 11 |

High reliability |

Low reliability |

● Energy Saving

By using the submersible circulation cooling water system, as water upstream of turbine is not be used for cooling water purpose; therefore, concurrent energy loss is avoided.

As no primary pumping is required, auxiliary consumption is reduced to that extent.

● Environment Friendly and Safety

Since the cooling water in the submersible circulation cooling water system is very clean, it will prevent unit from wear and tear of the cooler tubes of coolers, which may result in oil leaking into the river polluting the river water and failure of the bearing due to damaged heat exchangers. It can also reduce downtime of units arising due to silt erosion/damage of bearing/ generator coolers etc.

To sum up, the Circulation Type Cooling Water System, which has been in operation since 1989 has been extremely successful. This system, which can prevent sediment, floater, scale formation, aquatic organism, etc., is an advanced, proven, practical, economical cooling water supply system for hydro power stations. It establishes highly reliable supply of the cooling water. By use of this system, down time of generating units due to the cooling water gets practically eliminated. Never the less, this system also may ensure mitigating condensation issues. Undoubtedly, once installed this system proves its worthiness in no time by increased generation through high reliability as well as easy maintainability.

We are the leading company in China for the design, manufacturer of circulation cooling water system for the hydropower stations, with experience of more than 1,000 reference systems supplied and working at different installations, we believe that we can provide the best quality products and services to our customers worldwide.

Taihe Electric entered into the power industries since 2007, is a professional designer & supplier of thermal power equipment, spare parts and services and also a professional hydropower project water to wire package solution provider.

ADDRESS:Room 2002, 20th Floor, Block B, Jinsha Wanrui Center, No. 1 Shujin Road, Qingyang District, Chengdu City, Sichuan Province